|

Following

this shot, I got under with the nylon flapper again to really clean this

area up. |

|

After temporarily

removing the raised fiberglass section directly behind where the bumper

wings (facing forward) would sit, we test-fitted the new fender. |

|

The fit is quite

good, but due to the much wider fender, an extension of the support

panel between the inner body and the new fender will be necessary at the

rear of the wheelwell. |

|

|

The arrow on the larger photo (click on this photo) represents the

original stock fender line.

|

Can't wait to see a wheel and tire under there....this one, for example.

The wrench represents the width of the original 7.75x15" tires.

|

|

|

|

Due to the increased

width of the new fenders, the rear splash shields need to be widened.

Step one - cut and spread. |

| View

from in front. |

|

|

Step two........lay in

the fiberglass cloth and resin. |

Step

three......make it look nice.  |

|

|

Prior to working on

the new passenger side fender, this is a test fit of the new lower rear

valance (also referred to as the exhaust panel). Both the front and rear

lower valance panels were cracked, years ago, by the pumping action of

floor jacks when in a "hurry" to change wheels and tires.  |

|

Fender

is bonded in place.

|

|

|

The passenger side

rear fender is cut off. Now, I'll get under there with the flapper

to clean it all up. |

|

The plan is to cut

away everything but the raised fiberglass section (that sits behind the

bumpers) and slide the new fender in behind it. (EDIT:

Didn't do it that way. The narrow left-over portion would have broken

off anyway, so it was cut off. See next chapter for how it was bonded on

to the new fender.) |

|

After

clean-up, it'll be time to bond another new fender on.

|

|

|

Test fitting the

passenger rear fender. |

|

Here's

what the driver's rear splash shield area looks like "after"

the fender was bonded on. Some minor finishing and this portion is ready

for prime.

Wondering what the two holes are?

Chevrolet didn't bother changing the panel after dropping the earlier

power antenna option for 1967. The motor would mount behind this panel

using those holes. |

|

|

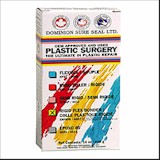

After discussions with

people at General Motors, the decision was made to use Dominion Sure

Seal Plastic Repair for bonding on of the fenders, lower front valance

and front signal light panels. The specific mix is called "Rigidflex

Bonder".

Very good product to work with,

but very expensive!

|